PaulsonTraining | Thermoforming Lesson 2: – Plastic Materials and Properties @PaulsonTraining | Uploaded 9 years ago | Updated 11 minutes ago

For a Free Trial of Thin Sheet Thermoforming, call 1-800-826-1901 or visit our website and request a trial here:

http://www.paulsontraining.com/Thermoforming

================================================

Thin Gauge Thermoforming Lesson 2 - Thermoforming Process: Plastic Materials and Properties

This section explains many of the forming methods used to develop specific part properties, with emphasis on looking inside the forming process to see what happens to the plastic. For tooling personnel, it’s important they understand the effects of each type of forming and type of mold on the formed parts.

================================================

Thermoforming is one of the most common processes for making a wide variety of consumer and industrial plastic parts. It’s also one of the fastest growing of the plastics manufacturing industries and employs thousands of personnel. While simple in concept, thermoforming is a complex process requiring knowledgeable and skilled personnel at all levels in the plant.

Highlights of what's covered in this 6 lesson (10 hours) Thin Gauge Thermoforming interactive training program...

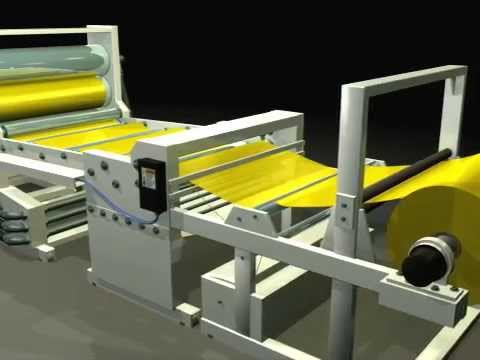

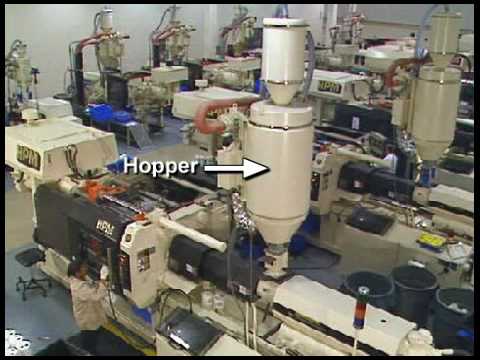

• Each step in the thermoforming process is explained using actual in-plant footage and High Definition 3D animation.

• The behavior of the molten plastic and its effects on part properties is explained and also shown using detailed graphics.

• How each step in the thermoforming process - heating, forming, and trimming - effect the thermoformed parts.

• Since the thermoforming process starts with sheet extrusion, the course also covers extrusion and sheet extrusion fundamentals

• How to optimize control settings, safety around the thermoforming machinery and thermoforming for maximum efficiency and profit.

Thin Gauge Thermoforming is recommended for: Operators, Setup Personnel, Process Technicians, Maintenance Technicians, Process Engineers, Project Engineers

For a Free Trial of Thin Sheet Thermoforming, call 1-800-826-1901 or visit our website and request a trial here:

http://www.paulsontraining.com/Thermoforming

================================================

Thin Gauge Thermoforming Lesson 2 - Thermoforming Process: Plastic Materials and Properties

This section explains many of the forming methods used to develop specific part properties, with emphasis on looking inside the forming process to see what happens to the plastic. For tooling personnel, it’s important they understand the effects of each type of forming and type of mold on the formed parts.

================================================

Thermoforming is one of the most common processes for making a wide variety of consumer and industrial plastic parts. It’s also one of the fastest growing of the plastics manufacturing industries and employs thousands of personnel. While simple in concept, thermoforming is a complex process requiring knowledgeable and skilled personnel at all levels in the plant.

Highlights of what's covered in this 6 lesson (10 hours) Thin Gauge Thermoforming interactive training program...

• Each step in the thermoforming process is explained using actual in-plant footage and High Definition 3D animation.

• The behavior of the molten plastic and its effects on part properties is explained and also shown using detailed graphics.

• How each step in the thermoforming process - heating, forming, and trimming - effect the thermoformed parts.

• Since the thermoforming process starts with sheet extrusion, the course also covers extrusion and sheet extrusion fundamentals

• How to optimize control settings, safety around the thermoforming machinery and thermoforming for maximum efficiency and profit.

Thin Gauge Thermoforming is recommended for: Operators, Setup Personnel, Process Technicians, Maintenance Technicians, Process Engineers, Project Engineers