James Bruton | Experimental Wave Drive V2 @jamesbruton | Uploaded 1 year ago | Updated 4 hours ago

Ad: You and your company can try Onshape for Free at https://Onshape.pro/JamesBruton

Check out the new CAM features coming to OnShape soon: onshapelive.com/event/ad95f7af-999c-4126-ba77-e5f615008895/summary?utm_source=jamesbruton&utm_medium=youtube

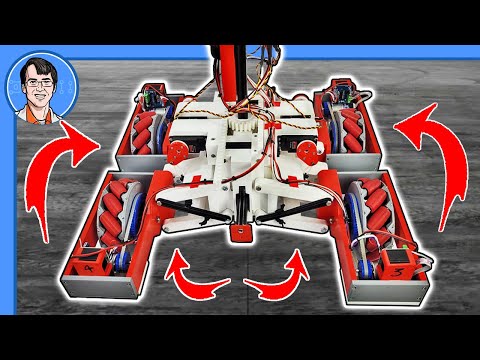

I previously built an experimental wave drive. I built a tank with two of these drives which worked fairly well. Each of the drives consists of a flexible track to make the wave shape, and inside is a spiral shaped piece of steel which rotates and shapes the flexible track as it does so.

I got this idea from another YouTube video, but this one is a single wave drive with steering wheels at the front.

This mechanism is a bit like a screw tank, but it allows us to manage the sideways friction from the screws because they turn inside the track, rather than having them running directly on the ground.

But what actually makes it go along? It seems clear that there’s a wave moving backwards or forwards and pushing the tank in the opposite direction, but surely each segment of the track is actually stationary and just moving up and down.

I had a lot of problems shaping the spiral parts properly in this version, I could probably have gone about it differently, but a few people in the comments suggested a different approach which was to use a cam shaft to make the wave instead of the spiral parts. If the cam shaft is mounted above the track then it’ll also help with ground clearance which was a problem I had because I needed a pulley to drive the rotary motion.

To start with I’m not going to design the track, so we’ll just push some flat plates up and down and see if that drives it along.

CAD: github.com/XRobots/WaveTank/tree/main/CAD

You can support me on Patreon, join my Discord, or buy my Merchandise:

***************************

Discord: discord.com/invite/fc6MedG7eW

Patreon: patreon.com/xrobots

Merchandise: teespring.com/stores/james-bruton

***************************

Other socials:

***************************

Instagram: instagram.com/xrobotsuk

Twitter: twitter.com/xrobotsuk

Facebook: facebook.com/xrobotsuk

***************************

Affiliate links - I will get some money of you use them to sign up or buy something:

***************************

10% off at 3dfuel.com - use code XROBOTS at the cart screen.

Music for your YouTube videos: http://share.epidemicsound.com/xrobots

***************************

CAD and Code for my projects: github.com/XRobots

Huge thanks to my Patrons, without whom my standard of living would drastically decline. Like, inside out-Farm Foods bag decline. Plus a very special shoutout to Lulzbot, Inc who keep me in LulzBot 3D printers and support me via Patreon.

HARDWARE/SOFTWARE

Below you can also find a lot of the typical tools, equipment and supplies used in my projects:

Filament from: 3dfuel.com

Lulzbot 3D Printers: http://bit.ly/2Sj6nil

Bearings from: simplybearings.co.uk

Lincoln Electric Welder: bit.ly/2Rqhqos

CNC Router: bit.ly/2QdsNjt

Ryobi Tools: http://bit.ly/2RhArcD

Axminster Micro Lathe: http://bit.ly/2Sj6eeN

3D Printer Filament: http://bit.ly/2PdcdUu

Soldering Iron: http://bit.ly/2DrNWDR

Vectric CNC Software: http://bit.ly/2zxpZqv

Ad: You and your company can try Onshape for Free at https://Onshape.pro/JamesBruton

Check out the new CAM features coming to OnShape soon: onshapelive.com/event/ad95f7af-999c-4126-ba77-e5f615008895/summary?utm_source=jamesbruton&utm_medium=youtube

I previously built an experimental wave drive. I built a tank with two of these drives which worked fairly well. Each of the drives consists of a flexible track to make the wave shape, and inside is a spiral shaped piece of steel which rotates and shapes the flexible track as it does so.

I got this idea from another YouTube video, but this one is a single wave drive with steering wheels at the front.

This mechanism is a bit like a screw tank, but it allows us to manage the sideways friction from the screws because they turn inside the track, rather than having them running directly on the ground.

But what actually makes it go along? It seems clear that there’s a wave moving backwards or forwards and pushing the tank in the opposite direction, but surely each segment of the track is actually stationary and just moving up and down.

I had a lot of problems shaping the spiral parts properly in this version, I could probably have gone about it differently, but a few people in the comments suggested a different approach which was to use a cam shaft to make the wave instead of the spiral parts. If the cam shaft is mounted above the track then it’ll also help with ground clearance which was a problem I had because I needed a pulley to drive the rotary motion.

To start with I’m not going to design the track, so we’ll just push some flat plates up and down and see if that drives it along.

CAD: github.com/XRobots/WaveTank/tree/main/CAD

You can support me on Patreon, join my Discord, or buy my Merchandise:

***************************

Discord: discord.com/invite/fc6MedG7eW

Patreon: patreon.com/xrobots

Merchandise: teespring.com/stores/james-bruton

***************************

Other socials:

***************************

Instagram: instagram.com/xrobotsuk

Twitter: twitter.com/xrobotsuk

Facebook: facebook.com/xrobotsuk

***************************

Affiliate links - I will get some money of you use them to sign up or buy something:

***************************

10% off at 3dfuel.com - use code XROBOTS at the cart screen.

Music for your YouTube videos: http://share.epidemicsound.com/xrobots

***************************

CAD and Code for my projects: github.com/XRobots

Huge thanks to my Patrons, without whom my standard of living would drastically decline. Like, inside out-Farm Foods bag decline. Plus a very special shoutout to Lulzbot, Inc who keep me in LulzBot 3D printers and support me via Patreon.

HARDWARE/SOFTWARE

Below you can also find a lot of the typical tools, equipment and supplies used in my projects:

Filament from: 3dfuel.com

Lulzbot 3D Printers: http://bit.ly/2Sj6nil

Bearings from: simplybearings.co.uk

Lincoln Electric Welder: bit.ly/2Rqhqos

CNC Router: bit.ly/2QdsNjt

Ryobi Tools: http://bit.ly/2RhArcD

Axminster Micro Lathe: http://bit.ly/2Sj6eeN

3D Printer Filament: http://bit.ly/2PdcdUu

Soldering Iron: http://bit.ly/2DrNWDR

Vectric CNC Software: http://bit.ly/2zxpZqv